What would make a consumer switch from a petrol or diesel-powered vehicle to greener and cleaner electric technology? And why might a fleet manager at a haulage and logistics organisation also follow this path to more sustainable transport options?

What would make a consumer switch from a petrol or diesel-powered vehicle to greener and cleaner electric technology? And why might a fleet manager at a haulage and logistics organisation also follow this path to more sustainable transport options?

The answers to these two questions have a surprising amount of commonality. Time and again, range and recharge time are cited as the biggest factors influencing the uptake of electric vehicles, from individuals and businesses alike.

Crucially, then, the aim to reduce charge time while increasing battery capacity is resulting in the development of some exciting new technologies. Graphene-based Hall effect sensors, for example, hold the potential to revolutionise battery characterisation and testing, enabling developers to make faster, more accurate measurements, thereby helping them deliver better performing EVs sooner.

Characterisation challenges

Research and development into new and improved EV battery technologies is a hotbed of activity, with pressure mounting to find viable solutions. One of the key challenges for developers is characterisation. The process involves analysing different cell chemistries and the physical processes occurring within new or modified designs. Measuring current density within the cell is a critical aspect, providing visibility of the internal workings, such as changes in cell resistivity.

State of charge measurements can be achieved using Coulomb counting techniques and instantaneous measurement of current inflows, outflows, and cell voltage. The aim is to ensure uniform charge distribution and heat dissipation. To date, a current density map of a cell could only be produced by the indirect method of temperature measurement. If temperature hotspots occur, they can indicate changes in the cell’s internal resistance due to physical processes. Cell temperature can be measured in many places. However, most externally mounted temperature sensors will exhibit a degree of lag between the temperature change occurring and the sensor element observing the change. Importantly, this lag may hide changes in the cell’s attributes that could lead to potential failure and thermal runaway.

A more direct method of measuring current density is possible using magnetic field sensors. Unfortunately, such devices have not, so far, been able to offer the combined spatial resolution, field resolution and dynamic range required for today’s EV cells. With conventional silicon-based magnetic sensors, the planar Hall effect has always proved problematic. This can lead to false measurement signals, which can ultimately impact measurement accuracy.

Two-dimensional solution

Enter Paragraf’s expertise with graphene: Graphene offers many unique technical characteristics that provide significant benefits over existing technologies. First, its one-atom thick composition makes it possible to measure in one plane, resulting in more accurate measurements and simpler system design. Crucially, graphene-based sensors can be optimised for low field environments and normal ambient temperatures, and their small footprint allows for good spatial resolution.

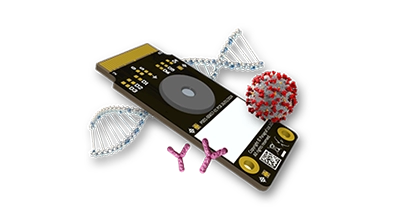

The Paragraf GHS-A sensor provides the perfect platform from which battery manufacturers can create high-performance cells. Within a test environment, multiple GHS sensors can monitor many different cell parameters, and provide insightful advantages throughout the development process.

- Flexible current measurement: By placing sensors beside the cathode and anode cell connections, the absolute current can be observed. Large fluctuations of current can also be monitored, and changes in the cell’s internal resistance calculated by the difference in current flows observed at the cell terminals.

- Density mapping in real-time: Using multiple sensors placed on the cell’s external surface permits recording and analysing the local variations of current within the cell in real-time, helping pinpoint current hotspots and potential points of failure.

- Deeper insight into current flow direction: The sensor can determine the direction of current flow, assisting in mapping differences in current flow path during charge and discharge cycles.

- Faster identification of failure modes: Changes in the cell’s internal resistance may occur due to the chemical processes involved and achieving a uniform resistance across the cell is essential. With the current density mapping capabilities of the GHS sensor, potential hotspots may indicate points of failure that require further investigation.

- Cell design optimisation: Analysis of current density hotspots and known cell failures and observing active/inactive areas of the cell can provide vital insights during initial cell prototyping and pave the way for an optimised cell design.

- Quality control: During cell manufacturing, a GHS sensor testbed can provide a fast and efficient method of cell quality assurance. Checking cells for performance against specification and leakage currents assist in maintaining production standards.

- Enables cell reuse and recycling: battery cells from EV and other applications can be re-purposed through non-destructive screening using a GHS sensor testbed.

Informed insight for improved battery performance

Improving cell power densities and faster charging characteristics demand advances in battery cell analysis. Such analysis is a relatively new concept but understanding the internal current density map of a cell is paramount during research and development. The Paragraf GHS-A sensor delivers a level of magnetic field resolution and instantaneous response not previously possible with traditional technologies.

Clearly, with better and more informed insight into what is happening inside a cell, battery manufacturers can respond to the automotive industry’s needs to increase EV range and improve charging efficiency. For the future, Paragraf’s graphene Hall effect sensor may become a standard cell component for next-generation battery management systems that aim for even higher performance.

To find out more about the application of graphene sensors in EV battery cell analysis, download our whitepaper.