Paragraf CCO Tom Wilson visited Taiwan to receive the “Taiwan Innotech Expo” (TIE) award and introduce the company and its graphene-based electronic devices, including magnetic and current sensors. The TIE Award is a contest organised by Taiwan’s Ministry of Science and Technology, Ministry of Economic Affairs to recognise cutting-edge technologies. The award attracted 119 start-up companies from 25 countries. After the initial review, 30 made it through to the semi-finals, including nine overseas companies from USA, Japan, Germany, Israel, Czech Republic, UK, Canada and Chile. Paragraf won third place and was the only overseas company in the top 3, a great recognition of its innovation in the mass production of graphene-based electronic components using standard semiconductor processes.

This post summarises the introduction to Paragraf.

Paragraf is the first in the world to use graphene to mass produce electronic components

Paragraf is the first in the world to use graphene in the mass production of electronic components using standard semiconductor processes for a wide range of critically important global challenges.

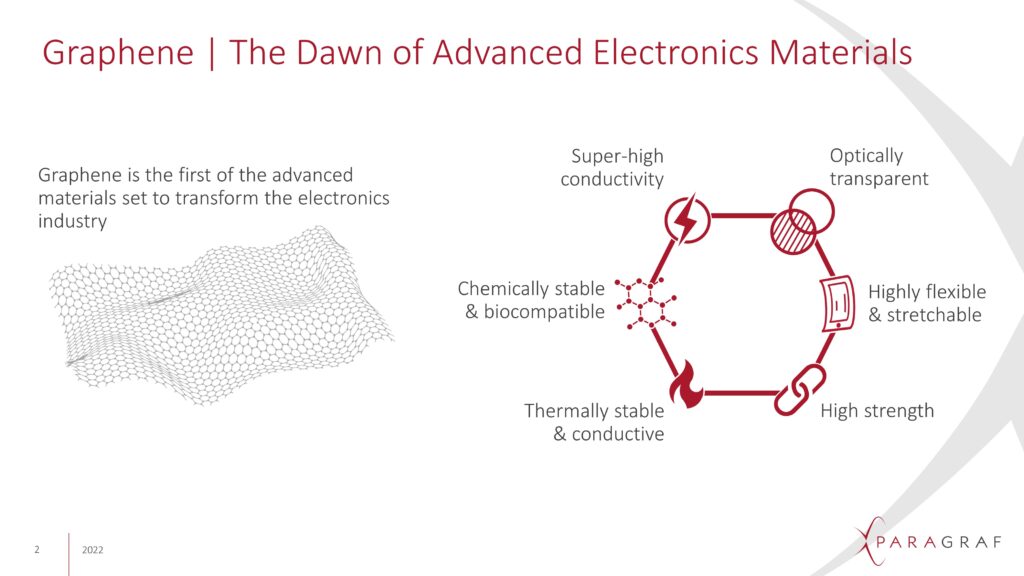

Graphene is the first of a new set of materials that are set to transform electronics as we know it. It is the dawn of advanced electronics materials. For those not familiar with graphene, it was discovered in 2004 in Manchester, UK. And in 2010 there was a Nobel Prize awarded to the two men who discovered it.

Graphene is a two-dimensional, one atom thick sheet of carbon atoms that are arranged in a hexagonal array. And it has for some time been viewed as a miracle material because of a really interesting set of special attributes. For example, it has extremely high conductivity, 1,000 times that of copper, which makes it ideal for the next generation of transistors.

Many are familiar with Moore’s Law, where the advantages we get of going smaller, submicron, have been flattening out over time. Graphene has the promise of rebooting Moore’s Law. It’s optically transparent, which makes it ideal for use in some optoelectronic applications for optical switching. It’s highly flexible and stretchable, which makes it amenable for a whole new set of bio electronics.

It’s high strength, so we can make highly durable, extremely rugged displays and touch screens. It’s thermally stable and extremely thermally conductive for a new range of thermal management possibilities. It’s chemically stable and biocompatible. That is immense because this introduces a whole new horizon for biosensors and clinical diagnostics that are now faster, less expensive, and more available to more people, saving more lives.

So it’s not surprising that the world has been holding its breath for some time to be able to take full advantage of this miracle material. But the challenge has been to mass produce graphene in electronics with standard semiconductor processes. Paragraf has actually done that. Paragraf has made graphene an industry ready solution.

Paragraf graphene is industry ready

In order to mass produce graphene-based devices, it was important to make the manufacturing process repeatable – to be able to do it over and over again in mass production. In addition, the 2D graphene that is deposited on the wafer substrate must be contaminant free and done in a way that is industry standard so that it’s integrable: we can integrate it into standard manufacturing processes.

So going from graphene production to graphene processing, to actual graphene devices, has been done. Paragraf has made it possible for wafer scale mass production of graphene devices. This means that we can now fully realize the promise of graphene. We can now begin to apply graphene to some really critical global challenges.

Using graphene in a wide range of globally critical challenges

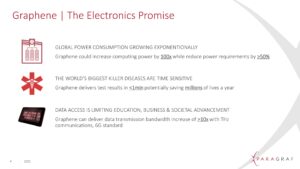

We have global power consumption issues and exponential growth in the energy consumption of data centres, Graphene has the potential to increase compute power by a factor of 100 times at half the power.

Here’s another issue: the world’s biggest killer diseases are time sensitive; they move quickly. Graphene based biosensors for clinical diagnosis makes diagnosis much faster, much more cost effective and they can democratize clinical diagnosis.

A third issue to consider: data access throttles learning. It’s a bottleneck to learning and information exchange. Graphene can make it possible to bring to bear terahertz broadband to resolve that.

So, with the world’s first integrable, scalable graphene mass production capability, the revolution in advanced materials electronics has begun and Paragraf is leading the way. If you would like to learn more, click through this website or contact us.

The original video of this presentation can be viewed on the TIE Award Facebook page.